Toprated

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Testimonials

Jesica Wilson

developerLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod...

Jesica Wilson

developerLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod...

Jesica Wilson

developerLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod...

Bestseller

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

Vendor

Example product title

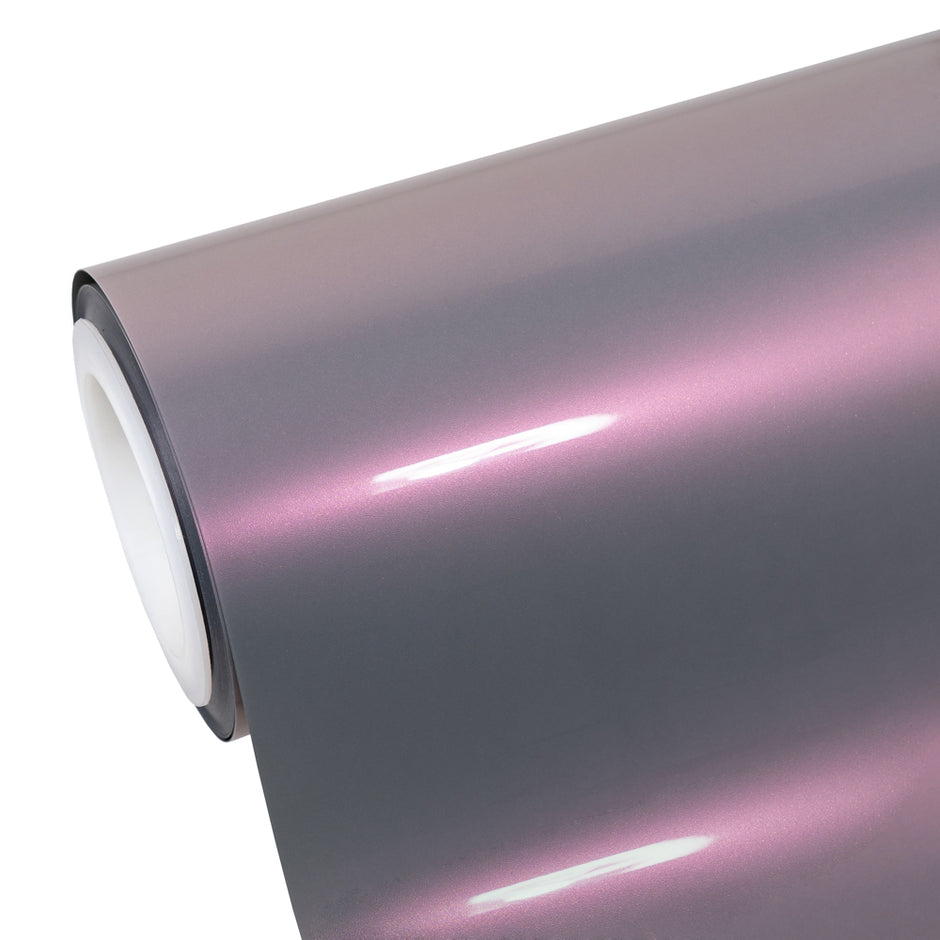

Candy Metallic Gray Pink Color PPF (Paint Protection Film)

Couldn't load pickup availability

-

Vendor:

718 AUTO SOUND

Description

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.

Wrap your car in superb radiance with the Candy Metallic Gray Pink Color Paint Protection Film by Vinyl Frog. This is not just a shield for your vehicle’s original paintwork; it is a complete upgrade for your ride, giving it a statement finish. The amazing shade of this PPF blends cool gray with warm pink and a high gloss finish that holds the gaze. Crafted from durable polyurethane, it is built to withstand the daily demands of driving and harsh environmental exposure. It offers robust resistance to scratches, corrosion, and weathering, making it an ideal choice for those who seek both style and substance in automotive protection.

Our Gray Pink PPF Wrap uses a strong, acrylic-based adhesive for reliable bonding. It has a self-healing topcoat that allows minor scratches and swirl marks to disappear when exposed to heat. This innovative feature helps preserve the smooth, glossy finish and extends the film’s aesthetic longevity. It is also hydrophilic and repels water, dirt, UV rays, and various forms of contamination. It is a dry application PPF film that makes installation a breeze by eliminating the mess and complications often associated with wet methods. Order now and get ready to protect your car with flair and confidence.

Features

- Smooth, glossy color finish for a sleek appearance

- Made from high-performance, durable TPU material

- Self-adhesive film with strong, acrylic-based adhesive

- Heat-activated self-healing topcoat to repair minor scratches

- Hydrophobic surface that resists UV rays, stains, and corrosion

- Scratch-resistant and anti-corrosion for long-term surface protection

- Suitable for dry application, offering a cleaner, more efficient installation process

- Equipped with air-release channels for bubble-free results

- Easy to apply, slide, reposition, and maintain

Specifications

- Application Method: Dry Application.

- Color: Gray Pink.

- Finish: Smooth candy metallic.

- Sizes available: 5ft x 3.3ft, 10ft, 16ft, 33ft, and 49ft.

- Packaging: Roll.

Things You Should Know

Best Paint Protection Film (PPF)

How To Apply Paint Protection Film

How Long Does Paint Protection Film Last?

How Much Does Paint Protection Film Cost?

Video

Structure

Functions

Recommended Uses

▲ Standard Size & Appearance

| Classification | Unit | Specs | Remarks | |

|---|---|---|---|---|

| Thickness | Top protected film | um | 50±5% | PET |

| Self-healing Layer | um | 10±5% | / | |

| Face Film | um | 60±3 | Thermoplastic Polyurethane | |

| Color Layer | μm | 17±0.5 | / | |

| Base Color Layer | μm | 70±0.5 | Termoplastic Polyurethane | |

| Acrylic Adhesive | um | 35±2 | Solvent-based | |

| Release liner | um | 75±5% | Satin Semi-transparent White | |

| Width | m | 1.52±1% | 4.98ft | |

| Length | m | 15±1% | 49.21ft | |

Physical properties

▲ General Properties

| Features | Test Method/Conditions | Data | |||

|---|---|---|---|---|---|

| Gloss(60°) | GB 8807 | ≥90 | |||

| Water Contact Angle | DL/T864 Appendix A | ≥90° | |||

| Hardness | GB/T 6739 | ≥85A | |||

| Elongation at Break | GB/ T1040 | ≥350% | |||

| Coating Elongation at Break | GB/ T1040 | ≥85% | |||

| Tensile Strength | GB/ T1040 | ≥18 (mpa) | |||

| Initial Adhesion | FTM 9 | ≥ 8N/25mm | |||

| 24h 180° Peel Force | GB/T 2792 | ≥ 12N/25mm | |||

| Storage Aging Peel Force | GB/T 2792 | ≥ 10N/25mm | |||

| Application Aging Peel Force | GB/T 2792 | ≥ 16N/25mm | |||

| Peel Force | GB/T 2792 | ≤ 0.3N/25mm | |||

| Dimensional Stability (MD) | FTM 14 | ≤ 0.5mm | |||

| Dimensional Stability (CD) | FTM 14 | ≤ 0.4mm | |||

| Scratch Repair | (0.1mm) Copper brush&Heat gun | Repair Time≤ 3minutes | |||

| Stain Resistance | GB/T 16422.2 | No visible water stain deposits | |||

| Hydrolysis Resistance | QC/T 1171-2021 | stable for over 200h | |||

| Acid & Alkali Resistance | Exposure to 10% hydrochloric acid and 0.1 mol/L sodium hydroxide solution for 24h | No visual coating defects | |||

| Yellowing ΔE | QUV Method 2000h | ≤2 | |||

| Application Termperature | / | +20℃ to +30℃ | |||

| ServiceTemperature | / | -50℃ to +110℃ | |||

| Recommended Shelf Life | 15-25°C or 59-77° F and 45-50% Humidity | 2 years | |||

| Warranty Period | / | 3-5 years | |||

Important Notice:

Information on physical property in this document are based upon tests we believe to be reliable. They are intended only as a source of information and are given without guarantee and do not constitute a warranty. Purchasers should independently determine, prior to use, the suitability of this material to their specific use.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable VinylFrog product packaging or product literature, VinylFrog warrants that each VinylFrog product meets the applicable VinylFrog product specification at the time VinylFrog ships the product.VinylFrog makes no other warranties or conditions, express or implied, including, but not limited to, any implied warranty or condition of merchantability or fitness for a particular purpose or any implied warranty or condition arising out of a course of dealing, custom or usage of trade. If the VinylFrog product does not conform to this warranty, then the sole and exclusive remedy is, at VinylFrog’s option, replacement of the VinylFrog product or refund of the purchase price.

Installation Conditions & Guidelines

To ensure optimal performance and long-lasting protection, please follow the installation instructions and environmental conditions below:

Recommended Installation Environment:

- Room Temperature: 25 ± 3°C

- Humidity: 50 ± 5% RH

- Cleanliness: Clean, dust-free environment with no visible airborne particles

Installation Instructions:

- Inspect the installation area for any conditions that may negatively affect the process. Resolve any defects or issues before proceeding.

- Thoroughly clean the vehicle's painted surface to remove contaminants such as mildew, oil, grease, stains, or other residues.

- Cut the film to the appropriate size. Do not remove the protective liner until just before application.

- Eliminate all bubbles, wrinkles, lifting edges, and other surface defects during installation.

- If the installed film fails to meet the required standards, remove and replace it with a new piece.

- Clean surrounding and adjacent surfaces to remove any excess installation solution.

- For one week after installation, avoid washing the vehicle or exposing it to rain to allow the adhesive to fully bond with the paint surface for maximum adhesion.

Recommendations

Recommended application tools: Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, sprayer, towel, and installation liquid

Application method: Standard methods for Paint Protection Film. Do not overstretch and overheat. Post-heating is necessary.

Post-heating temperature: 110°C flat surfaces, 130°C curves and overlaps.

Aftercare: PH neutral. Avoid wax or solvents.

Durability:

The durability is based on South China exposure conditions. Actual performance life will depend on substrate preparation, exposure conditions and maintenance of the marking. For instance, in areas of long high temperature exposure and in industrially polluted areas or high altitudes, exterior performance will be decreased.

CAUTION!

1. We will peel off the protection layer before shipment if your order is 1m,3m or 5m in order to make the vinyl good for shipping.

2. The images, colors, and finishes on the screen are approximate. For the real representation of the product always check the color swatch.